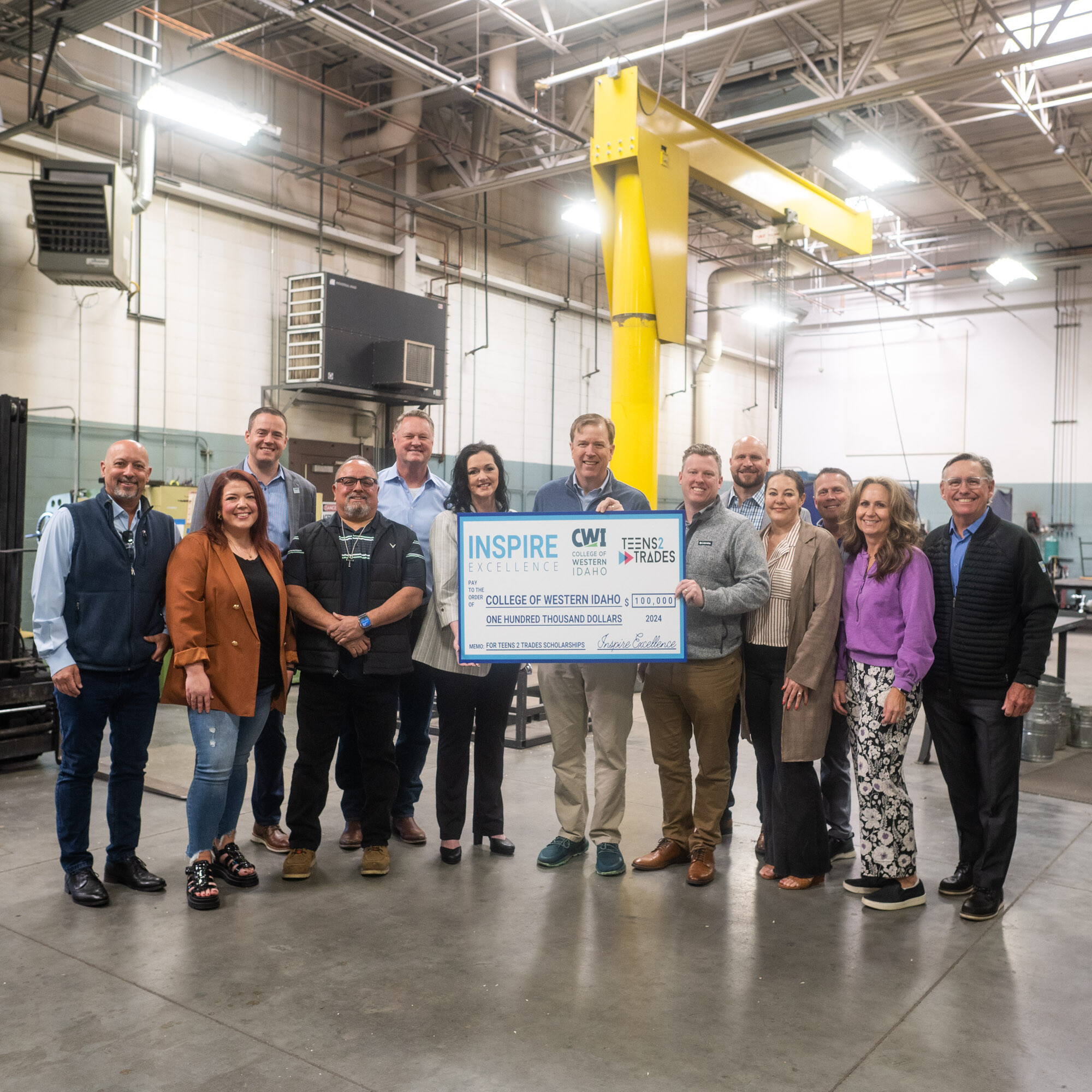

CWI received a $100,000 gift from the Teens 2 Trades program to fund scholarships for plumbing, electrical, HVAC, and welding students.

Read more about Trading Up: Scholarships at CWI Receive a $100,000 Boost from Teens 2 TradesWelding and Metals Fabrication

Harness the Power of Heat and Metal to Forge a Path to In-Demand Careers

Program Overview

Interested in a career that fuses creativity with precision? The Welding and Metals Fabrication program at College of Western Idaho (CWI) is an ideal choice. This program provides in-depth training in key welding techniques such as Shielded Metal Arc Welding (Stick), Gas Tungsten Arc Welding (MIG), Gas Metal Arc Welding (TIG), and Flux Cored Arc Welding. You will also master essential metalworking skills, including layout, cutting, and fabrication. A highlight of the program is the preparation for the American Welding Society (AWS) certification, highly valued in the industry.

Our program combines theoretical knowledge with extensive hands-on practice in our state-of-the-art workshops. You will learn from experienced professionals, gaining the skills to work on a wide range of projects, from industrial to custom metalwork. Whether starting a new career or advancing your skills, this program is your gateway to a successful career in welding and metals fabrication.

Degree or Certificate Type

Associate of Applied Science

Intermediate Technical Certificate

Basic Technical Certificate

Time to Complete

1 – 2 years

Primary Location

Program Exploration

Program Exploration – May 1

Learn more about the Welding and Metals Fabrication program, meet the instructors, and get your questions answered!

Learning Opportunities

- Welding Techniques: Master Stick, MIG, TIG, and Flux Cored Arc Welding, among other welding techniques.

- Fabrication Skills: Learn layout, cutting, and fabrication for a variety of metalworking projects.

- Safety & Standards: Adhere to industry safety standards and best practices in all operations.

- Technical Proficiency: Develop a deep understanding of welding equipment, materials, and techniques.

- Certifications: Be prepared for the American Welding Society industry-recognized certification.

Area of Study

Degrees & Certificates

Welding and Metals Fabrication – Associate of Applied Science Degree

Welding and Metals Fabrication – Intermediate Technical Certificate

Welding and Metals Fabrication – Basic Technical Certificate

Career Opportunities

Welders, Cutters, Solderers, and Brazers

Use hand-welding, flame-cutting, hand-soldering, or brazing equipment to weld or join metal components or to fill holes, indentations, or seams of fabricated metal products.

485

Annual Openings*

$21.72

Hourly Median Wage*

$45,178

Annual Median Salary

9.15%

Growth (2021 – 2031)*

Welding, Soldering, and Brazing Machine Setters, Operators, and Tenders

Set up, operate, or tend welding, soldering, or brazing machines or robots that weld, braze, solder, or heat treat metal products, components, or assemblies. Includes workers who operate laser cutters or laser-beam machines.

12

Annual Openings*

$19.53

Hourly Median Wage*

$40,622

Annual Median Salary

45.88%

Growth (2021 – 2031)*

*Data sourced from Lightcast™ (2023), a global leader in labor market analytics, and limited to the state of Idaho. Contact CWI Institutional Research for questions regarding this data.

Admissions

Step 1

- Apply to CWI.

- Choose Welding and Metals Fabrication as your major.

Step 2

- Complete the Free Application for Federal Student Aid (FAFSA).

STEP 3

- Attend a Welding and Metals Fabrication Program Exploration event prior to registering for classes.

Cost & Aid

As a student in this program, you may be eligible for financial aid and scholarships.

Lab Spaces

View the College’s state-of-the art lab spaces where you will receive hands-on, comprehensive career training.

Enrichment Opportunities

Enhance your academic experience, expand your knowledge, reach your goals, and celebrate your achievements.

Advising

Already a student? We are here to help you navigate your educational journey, connect you to academic and support resources, and achieve your academic or career goals.

Transfer Information

Plan ahead for a smooth transition to a four-year college or university.

News

After a $224,000 donation on April 8, The Nagel Foundation has now invested over $1M to support successful student outcomes at CWI.

Read more about Nagel Foundation Scholarship Fund Tops $1M in Donations After 6 Years Supporting CWI StudentsCWI's partnership with Idaho Job Corps serves students by connecting them to skills training and employment.

Read more about CWI's Partnership with Idaho Job Corps Helps Students ThriveThe Nagel Foundation scholarship empowers second-year career and technical education students to complete their education.

Read more about Nagel Foundation Continues Commitment to StudentsCongratulations to Bradley Dougal, a 2019-2020 Nagel Foundation scholarship recipient.

Read more about Education Sparks FutureCongratulations to Harvey Kenworthy, College of Western Idaho’s Staff of the Month for March 2019.

Read more about Staff of the Month—March 2019Emily Kominek is thriving as a Career Pioneer in the College's Welding program.

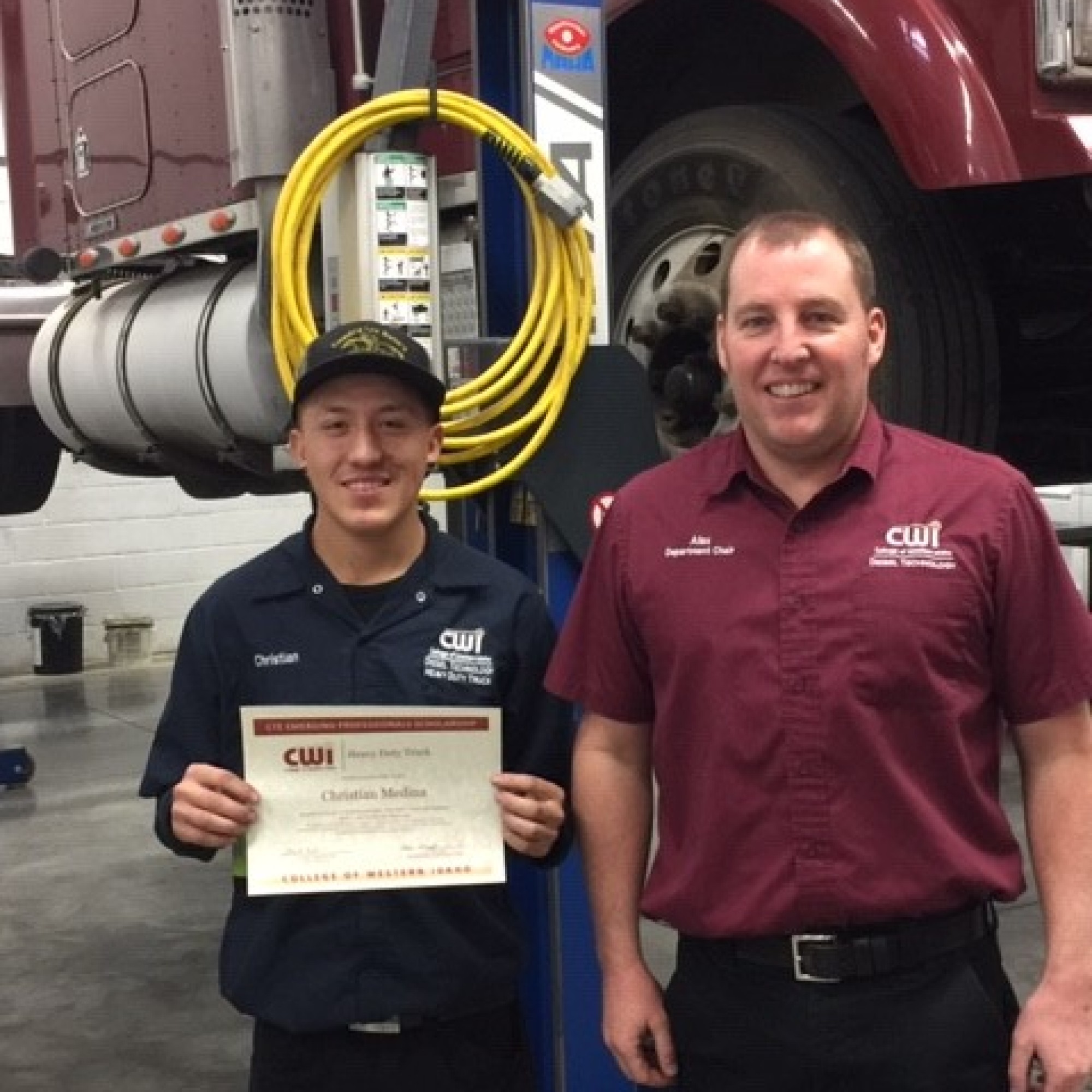

Read more about Career Pioneer: Emily KominekCareer and Technical Education students nominated by instructors as Emerging Professionals for 2018/19 academic year.

Read more about Emerging Professionals Nominated for Commitment, Talent, and PotentialBridge program gives high school seniors a head start in their welding career.

Read more about Pilot Program for Welding StudentsCollege of Western Idaho student, Yulonda King, has spent a lifetime learning to stand on her own two feet.

Read more about Standing StrongCWI swept away the competition with 37 medals at this year's SkillsUSA State Conference.

Read more about CWI SkillsUSA Wins Big at State CompetitionAn Idaho inspired, one-of-a-kind work of art is in Washington D.C. for the holidays thanks to a partnership forged between a pair of Treasure Valley organizations.

Read more about U.S. Holiday Tradition has CWI FlairRequest More Information

Connect With Us

Ready to get started? Our team looks forward to assisting you!